4000 DC Degas Conductivity Analyzer

Fast and accurate degassed conductivity monitoring with Waltron’s compact and innovative 4000 DC

The Waltron 4000 DC Degas Conductivity Analyzer utilizes innovative, dynamic degassing technology for precise conductivity measurements in ultra-pure water systems. Engineered for reliability and ease of use, it seamlessly integrates after cation exchangers. Supported by Waltron’s strong U.S. team, the 4000 DC ensures accurate, continuous monitoring with unmatched performance.

Key Features

- Revolutionary heatless degassing technology

- Achieves 93.5% degassing efficiency in less than 90 sec

- Sample temperature fluctuation does not affect accuracy

- No gas emissions or volatile acids

- Significantly reduced turbine start-up times

- Surface mount can be easily linked to a Waltron 9095 or 4095 Multicon

- Bright 3.5″ TFT color display shows precise values from specific and cation conductivity sensors, and generates a calculated pH value for the same sample point

- Easy to install and configure with alarms, relays, and two 4-20mA outputs per channel

- On-board data logging and live trending

- Choice of 24VDC or 110-240VAC versions

Specifications

- Parameter: Degas Conductivity

- Technology: Dynamic Degassing

- Range(s): 0-9.999 μS/cm

- Accuracy: (+/-) 1% of measured value or +/- 1 digit (whichever is greater)

- Sample Streams: 1

- Response Time: t90 < 30 sec

- Sample Frequency: Continuous

- Analog Outputs: Single current output, selectable 0-20mA or 4-20mA into 750 ohms max, fully isolated to 2kV. Expandable across the full operating range and offset anywhere in that range. Loop fault detection.

- Alarms: 2 normally open, fully configurable setpoints, with volt-free contacts for each relay.

- Calibration Method: Process

- Ambient Conditions: 0-55°C / (32-131°F)

- Sample Temperature: 0 – 50 °C / (32 – 122° F)

- Sample Flow/Pressure: 7-10L/h ; (.031 – .044 GPM) ; Maximum 10bar (145psig)

Mechanical

- Power: Universal 90-265vAC, 10W max. LV Option 12-30vDC, 5W max

- IP Rating: IP 66, NEMA 4X

- Mounting: Surface/wall

- Materials: Corrosion Resistant Steel and ABS plastic

- Sample Connection: 1/4 (0.635cm) OD Swagelok

- Maintenance Cycle: Monthly soda lime cartridge

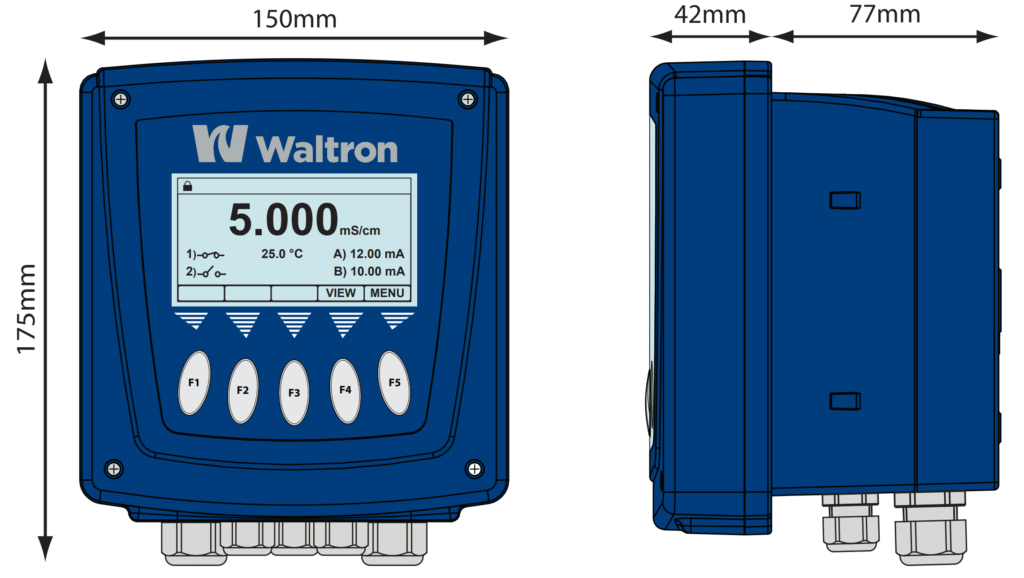

General Arrangement Drawing

PERFORMANCE

Range

0 to 9 999 uS/cm, 0 to 99.99 uS/cm

Accuracy

< 0.6% of the measuring range

Degassing Efficiency

93.5% in less than 90 seconds

User Interface

5.5” color touch screen

Alarms

General Alarm, Low Degassing Efficiency Alarm, Resin Exhausted Alarm

Analog Outputs

4 x 0/4 – 20 mA for measured signals

Data Storage

Extract via USB 2.0

Power

110 to 240 VAC. 48 to 63 Hz

Options

Optional RS422/RS485

Method

Meets ASTM D4519-16 for degassing method

OPERATING CONDITIONS

Sample Temperature

32 – 140° F (0 – 60 °C)

Ambient Temperature

32 – 131° F (0 – 55 °C)

Sample Flow Rate

031 – .044 GPM (7-10L/h)

Pressure

Maximum of 145 psig (10 bar)

Sample Medium

Liquid

MECHANICAL

Construction

Transmitter – high strength ABS. IP67

Wet Section – stainless steel or PVC

Dimensions

29 x 37 x 10″ (613 x 939 x 254mm)

Mounting

Wall mount or panel mount

Finish

Corrosion resistant