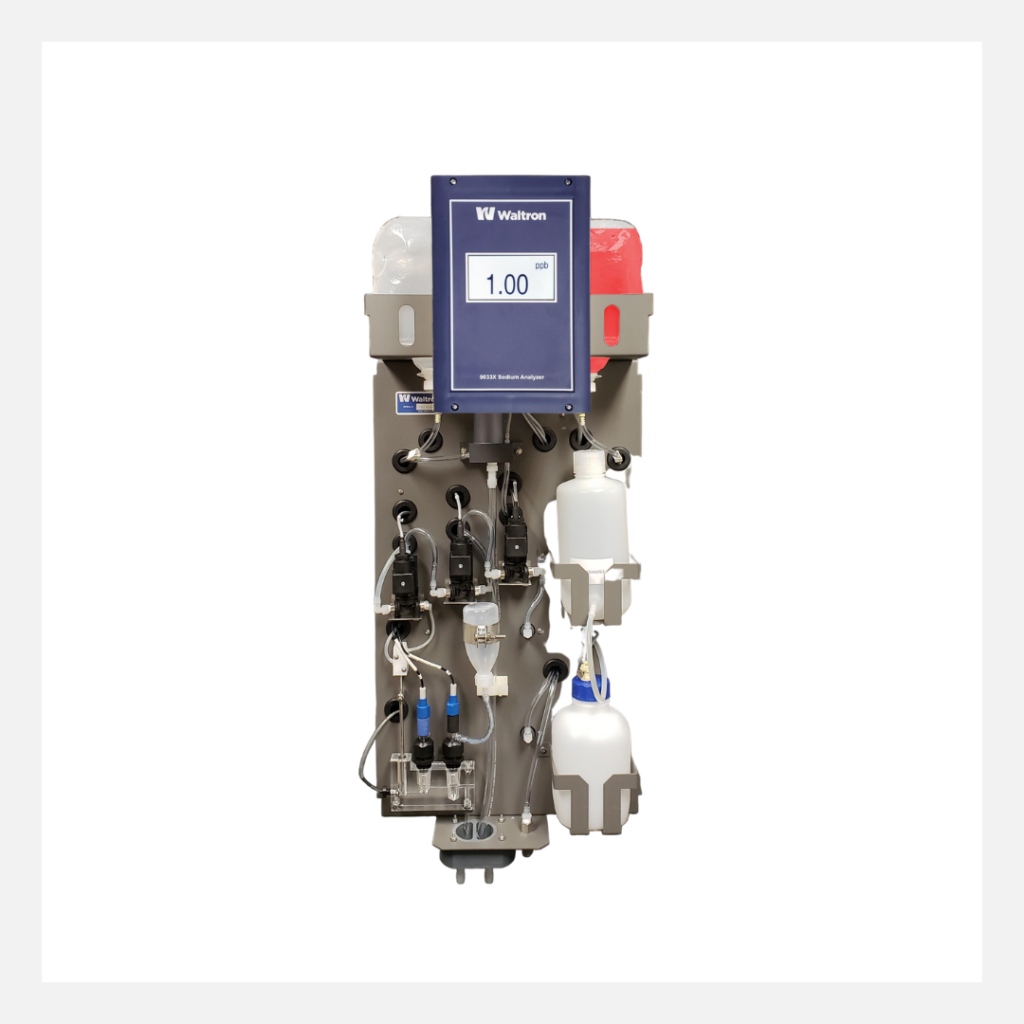

9033X Sodium Analyzer

Reliable Sodium Monitoring with Waltron’s 9033X for Ultrapure Water Systems

The Waltron 9033X Sodium Analyzer excels in ultrapure water applications, offering automatic calibration and low-maintenance features. Ideal for boiler systems, it measures sodium in make-up water, condensate, and steam. With a user-friendly interface, quick-connect electrodes, and strong service support, it ensures reliable and efficient monitoring.

Key Features

- Large, user-friendly color touchscreen interface

- Calibration: automatic 2-point or single point; user may select weekly, bi-monthly, or monthly calibration frequency as well as day and time

- Hassle-free maintenance: calibration standards andelectrode refill can last up to 3 months

- Low sample flow indication (optional)

- Quick connect electrodes and probe positioning clamps

- Automatic reference electrode electrolyte refill system

- Grab sample capability

- Two 4-20 mA isolated current outputs

- Internal data logger set to store readings every 10 minutes for 30 days

- Automatically logs last 10 alarms and results of last 10 calibrations

Specifications

- Parameter: Sodium

- Technology: Ion-Select Electrode

- Range(s): 0.10ppb-10ppm

- Accuracy: ±5% of reading or ±0.1ppb (whichever is greater) within ±5°C of calibration temperature

- Sample Streams: 1

- Response Time: 90% of 10-1ppb step: 3 minutes; 90% of 100-1ppb step: 5 minutes

- Cycle Time: Continuous

- Analog Outputs: 2 isolated 4-20mA

- Alarms: Low-flow alarm and 3 voltage-free contacts, alarm points set from transmitter rated at 2A, 250VAC (non-inductive)

- Calibration Method: Automatic

- Calibration Frequency: Weekly, semi-monthly, monthly (user set)

- Ambient Conditions: 0-55°C (32-131°F)

- Sample Temperature: 5-55°C (40-130°F)

- Sample Flow/Pressure: 150-400ml/min; 5-30psig (0.35-2.07bar)

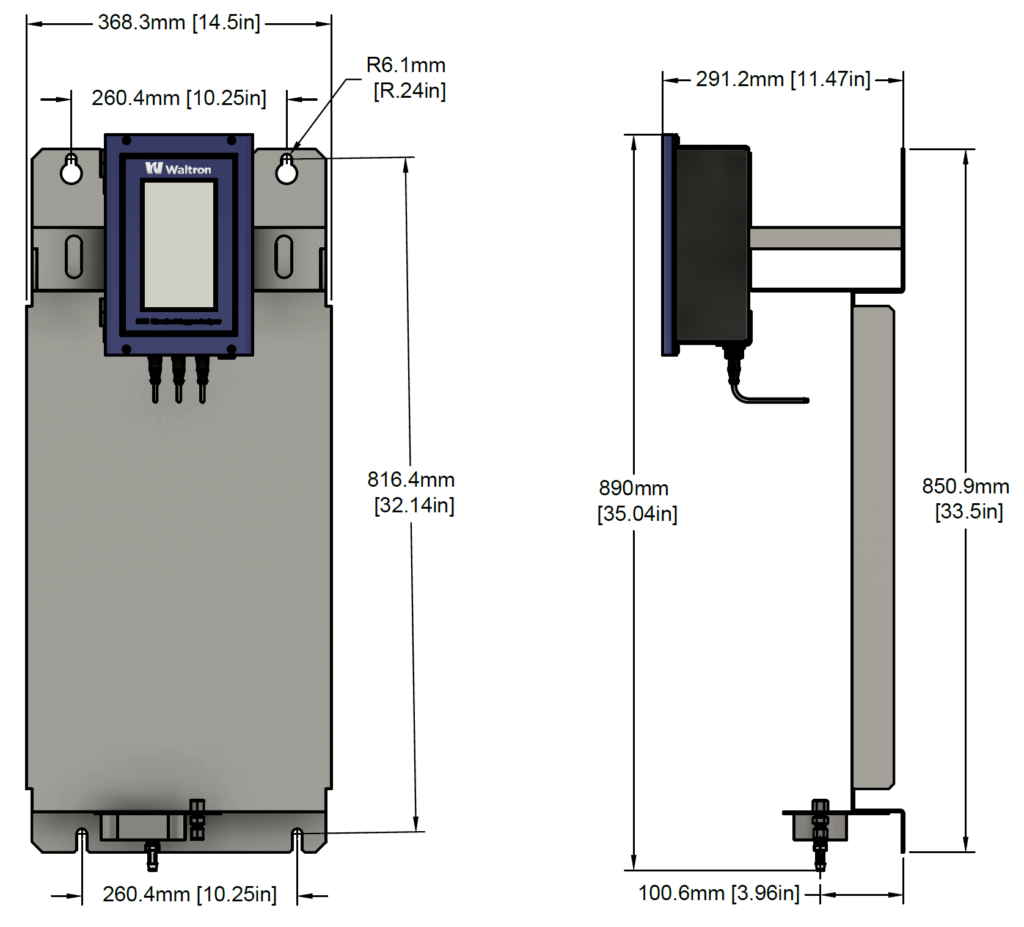

Mechanical

- Power: 90-250VAC, 50-60 Hz

- IP Rating: Transmitter: IP65/NEMA4X; Wet Section: IP55/NEMA4

- Dimensions: 85x37x28cm (33.5″x14.5″x11″)

- Weight: 15kg (33 lbs)

- Mounting: Wall

- Materials: Corrosion-resistant Stainless Steel

- Sample Connection: 1/4 (0.635cm) OD Swagelok

- Maintenance Cycle: Monthly, Quarterly

General Arrangement Drawing