DISCONTINUED: The 3041 Silica Analyzer is replaced by the updated 3141 Silica Analyzer.

3041 Silica Analyzer

Range: 0 – 300ppm

The Waltron 3041 Silica Analyzer is the first choice for online analysis of dissolved silica in ultrapure water applications. The 3041 is trusted worldwide to deliver reliable readings with minimal maintenance and a low total cost of ownership. An enhanced color touchscreen user interface makes the 3041 easy to operate and configure, and the clever fast-loop reservoir feature allows accurate measurement independent of flow. Common application points in a boiler system for online silica measurement include make-up water, condensate, boiler feedwater, saturated steam/main steam, and cooling water.

- Accurate and wide-range analysis

- Multi-stream available

- Fast loop reservoir

- Adjustable cycle and calibration frequency

- Automatic calibration and validation (QA/QC)

- Compact design

- Color touchscreen display

- Grab sample capability

- Internal datalogger

- Low reagent level alarm

- No compressed air is required

- Automatic start/stop based on sample flow detection

- Minimal analyzer maintenance

PERFORMANCE

Range

0 – 1000ppb, 0 – 5ppm, 0 – 150ppm, 0 – 300ppm

Accuracy

+/– 1 ppb or +/– 2% of reading, whichever is greater

Reproducibility

+/– 1 ppb or +/– 2% of reading, whichever is greater

Sampling Frequency (Cycle Time)

One reading every 20 mins, adjustable

Required Maintenance

Monthly or quarterly replenish reagents; Quarterly replace tubing

Reagent Consumption (approximate)

3 reagents, 2L each per month (optional 7.5L for 3 months)

Sensor Classification

Colorimetric with glass flowcell and LED source

Application

Boiler and Cooling Water.

Ambient Temperature Range

5-55°C analyzer (41-131°F)

Atmospheric Pressure Range

No Limits

Humidity

Up to 90% not condensable

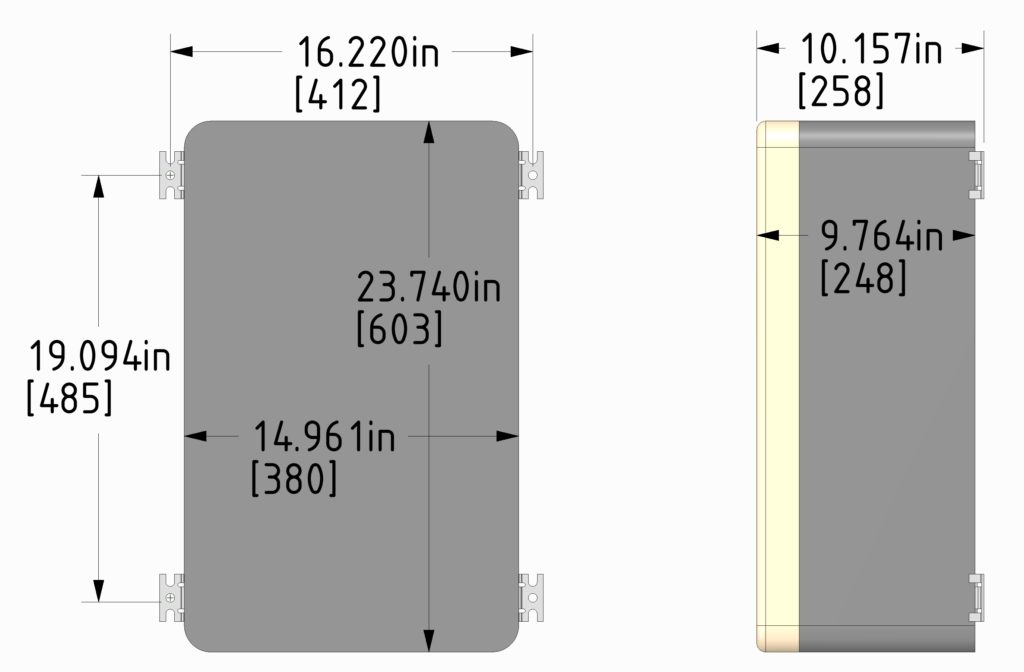

Unit Dimensions

Height = 26” (66.1cm), Width = 15” (38.1cm) Depth = 12” (30.5 cm)

Positioning and Installation Details

Wall mounting, bench-supported, or panel mounting (optional)

Weight

17 kg (37.5 lbs.)

Degree of Protection

IP55 (NEMA 4): Wet section, IP65 (NEMA 4x): Electronics

Alarms

2 or 4 configurable alarm relays (Result, loss of sample, fault)

Power Supply (on request)

110-220Vac, 50-60 Hz 80 VA

Certification (on request)

Meets low voltage and low electromagnetic compatibility directives

SAMPLE DELIVERY OPERATING CONDITIONS

Temperature Range

5-55º C (41-131º F)

Inlet Sample

100–500 ml/min, atmospheric, flexible tubing O.D. 1/4″(6mm)

Outlet Sample

Atmospheric, waste tubing O.D. 3/8″(9mm)

PH

3-12

Sample Conditioning Requirements

Filtering between 10 and 60 microns, depending on the matrix,

needed only to avoid clogging.

Materials in Contact with Sample

Glass, Silicone, Plexiglass, Stainless Steel AISI 316

SIGNAL OUTPUTS

Analog Outputs

4-20mA (galvanic isolator module available as option or 0-5V)

Serial I/O for Signals

Serial data output RS232; RS485; MODBUS; PROFIBUS

OPERATIONAL CALIBRATION

Single/Multi-Point

Multi-Point: zero and mid-range

Matrix Corrections

Yes, sample blank correction

Manual/Automatic

Both